The Preparation of Avocado Oil: A Quality Process from Origin to Your Table

Selection of Quality Avocados: Starting with the Best

Let’s begin with ripe avocados from the Chilean Mediterranean climate to ensure we capture that creamy and buttery flavor in every bottle. We use cutting-edge technology to select ripe avocados that meet our high quality standards.

Cold Pressing: The Secret to Preserving Oil Quality

The avocado pulp undergoes a washing process and is then mechanically separated from the peel and the pit. We employ state-of-the-art technology to ensure that the separation process is accurate and efficient. The pulp is sent to a specialized machine that utilizes high-precision technology to knead and heat the pulp in a controlled environment.

Cold Pressing Process: Preserving Beneficial Properties

Cold pressing is a method that utilizes minimal heat to extract oil from the avocado pulp. In our process, we ensure that the avocado pulp never exceeds 40 degrees Celsius (the international limit is 50 degrees) to maintain oil quality. We use high-tech monitoring systems to ensure that the pulp remains at the proper temperature throughout the process.

Care and Precision in the Separation Process

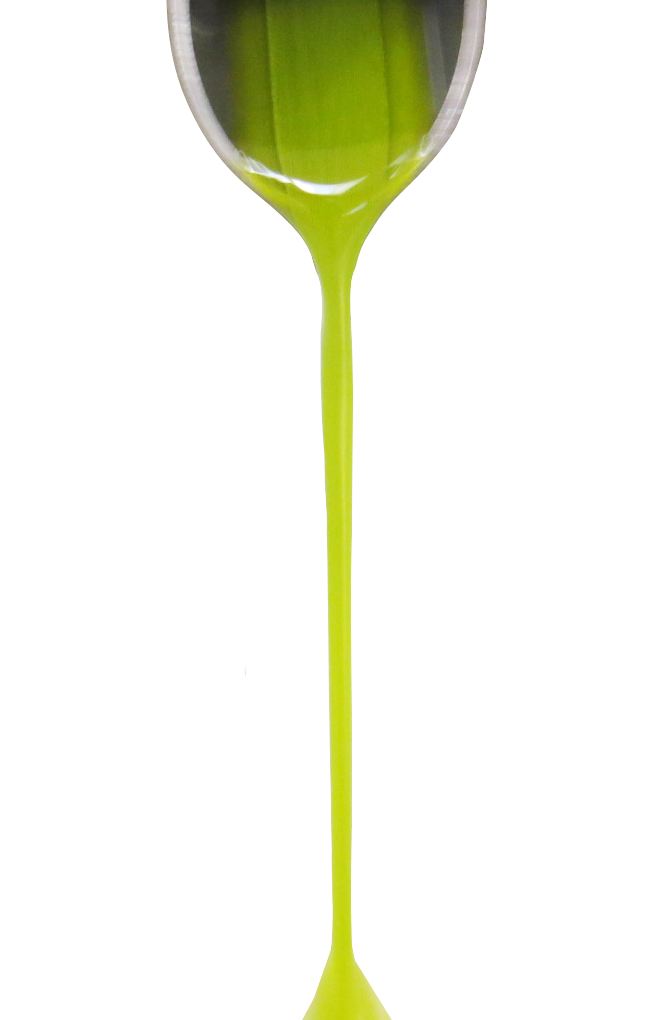

After a very short period of time, the pulp is sent to a high-tech centrifuge for separation. We use cutting-edge technology to ensure that the separation process is accurate and efficient. Once the solids have been separated from the oil, the intense green raw oil is sent to a final separation machine to remove additional particles.

Rigor in Quality Standards: Ensuring an Excellent Product

The oil from this machine is ready to be consumed without further processing. We ensure that the oil meets our quality standards before it is packaged and sent to the market. This meticulous process ensures that each bottle of Avocado Oil that reaches your table is a testament to quality and pure, natural flavor.